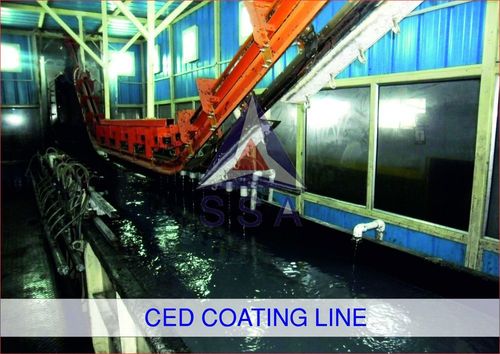

ED Coating Plant

Price 3000000 INR/ Unit

ED Coating Plant Specification

- Concentration

- Varies as per process

- Shelf Life

- 12 Months Months

- Tank Capacity

- 500 L to 20000 L Liter (L)

- Chemical Name

- Electrophoretic Paint

- Grade Standard

- Industrial Grade

- Ph Level

- 5 to 6

- Temperature Range

- 20C - 30C Celsius (oC)

- Packaging Type

- As per client requirement

- Usage

- Industrial

- Product Type

- ED Coating Plant

- Voltage

- 380V / 415V Volt (v)

- Power Source

- Electric

- Color Available

- Custom Colors Available

- Material of Construction

- Mild Steel / Stainless Steel

- Application

- Automotive Parts, Industrial Components, Appliances

- Surface Finish

- Smooth and Uniform

- Control System

- PLC Controlled

- Automation Grade

- Automatic / Semi-automatic

About ED Coating Plant

Product Details:

It is water based coating method done on metal components. Coating is done by keeping the component connected to a circuit as the cathode and positively charged paint particles (anode) suspended in aqueous medium are deposited under direct current. Deposited film does not re-dissolve and the un-deposited material is rinsed off.

Salient Features:

- Extremely high corrosion resistance, a 20 micron dry film thickness can withstand as much as 1000 hourssalt spray test ASTM B117

- Able to coat highly recessed areas

- Able to coat complex shapes with a very high degree of accuracy and repeatability

- Freshly deposited film is insoluble in water, permitting complete rinsing and recovery of dragged out material.

- Uncured paint is dry enough to allow careful handling

- Unlike Spray Coatings, CED Paint does not wash off in enclosed areas due to hot Vapours

- Simple process - eliminates dependence on skilled manpower. Fully automatic PLC based plant

- The deposited film is reproducible from part and from day to day

Precision Control and Seamless Operation

The ED Coating Plant integrates advanced PLC control, enabling precise management of every stage in the coating process. With the option of fully automatic or semi-automatic operation, users benefit from increased productivity and consistency-regardless of production volume. The mild steel or stainless steel construction ensures high durability and long-term performance, catering to both heavy-duty industrial and delicate appliance applications.

Superior Surface Finish and Customization

Our system applies electrophoretic paint for a smooth, uniform finish that enhances both the appearance and durability of coated parts. The plant operates efficiently at 20C to 30C and offers custom color options to match client specifications. Tank capacities ranging up to 20,000L allow scalability for small to large enterprises. With controlled pH and concentration parameters, quality is maintained in every batch.

FAQ's of ED Coating Plant:

Q: How does the ED Coating Plant ensure a smooth and uniform finish on parts?

A: The plant utilizes a PLC-controlled process to optimally regulate every aspect of electrophoretic painting, ensuring consistent agitation and temperature throughout. This controlled automation leads to reliable, smooth, and uniform coatings on each component.Q: What types of materials can the ED Coating Plant handle?

A: Constructed from mild steel or stainless steel, the plant is compatible with a variety of metal automotive parts, industrial components, and appliances, providing versatile application for diverse industries.Q: When is it advisable to use the automatic versus semi-automatic operation modes?

A: Automatic operation is best for high-volume production or when precise repeatability is essential, while semi-automatic mode offers flexibility for smaller batches or specialized components requiring manual oversight.Q: Where can the ED Coating Plant be installed?

A: The plant is suitable for installation in manufacturing facilities and industrial plants across India. Our team provides end-to-end support, including setup and customization to suit plant layouts and client requirements.Q: What is the typical process flow in the ED Coating Plant?

A: The process starts with component cleaning, followed by immersion in the electrophoretic paint tank. Under controlled pH (5-6) and temperature (20C-30C), electrical current deposits a uniform paint layer, which is then cured for durability.Q: What are the main benefits of using this ED Coating Plant for industrial applications?

A: Key advantages include improved corrosion resistance, enhanced surface durability, environmentally friendly operation due to controlled emissions, and customizable aesthetics. The automation also increases throughput and reduces labor costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CED Plants Category

Automatic CED Plant

Price 15000000 INR / Plant

Minimum Order Quantity : 1 Plant

Dimension (L*W*H) : 4000 x 3000 x 2500 mm Millimeter (mm)

Voltage : 220440 Volt (v)

Equipment Type : Electroplating Machine

Tank Capacity : 1000 Liters Liter (L)

CED Coating Plant

Price 500000 INR / Unit

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : Customizable as per requirement

Voltage : 415 V AC, 3 Phase, 50 Hz

Equipment Type : Other, CED Coating Plant

Tank Capacity : 1000 to 15000 Litres (customized)

Turnkey Industrial CED Plant

Price 3500000 INR / Number

Minimum Order Quantity : 1 Number

Dimension (L*W*H) : Customized as per project requirements

Voltage : 380415 V, Three Phase

Equipment Type : Other, Turnkey Industrial CED Plant

Tank Capacity : 1000 20000 Liters (customized)

Dunking Type CED Plant

Price 2200000 INR / Unit

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : Customized as per requirement

Voltage : 380415V, 3 Phase, 50 Hz

Equipment Type : Other, Dunking Type CED Plant

Tank Capacity : 100010000 Liters (customizable)

Get A Quote

Get A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS