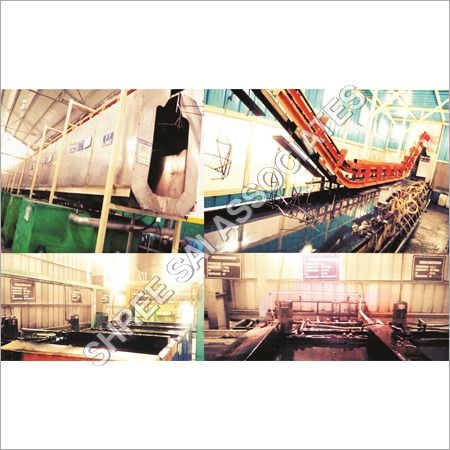

CED Plant

Price 5500000 INR/ Plant

CED Plant Specification

- Ph Level

- 7 to 8

- Shelf Life

- 2 Years

- Tank Capacity

- 1000 Liters Liter (L)

- Usage

- Industrial

- Equipment Type

- Electroplating Machine

- Size

- Standard

- Product Type

- CED Plant

- Color

- White

- Dimension (L*W*H)

- 4000 x 3000 x 2500 mm Millimeter (mm)

- Voltage

- 220-440 Volt (v)

CED Plant Trade Information

- Minimum Order Quantity

- 1 Plant

- Payment Terms

- Cash Against Delivery (CAD), Cash in Advance (CID), Cheque

- Supply Ability

- 10 Plants Per Year

- Delivery Time

- 7-8 Week

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About CED Plant

The CED Plant are carefully designed for the required surface area per lot/per unit of time to optimise bath size, no and size of anode cells, size of rectifier capacity of chiller, ultra filtration capacity etc. The other systems are common viz pre CED stages similar to pre-treatment and post CED as normal curing oven. The plants are offered with basic automation/interlock to high end automation.

We have been providing our esteemed clients with an excellent quality gamut of CED Plants. Offered industrial plants are assembled using very modern technology and the optimum quality components. Our provided industrial plants are meticulously inspected by a team of our proficient professionals. In addition, our dear clients can get these industrial plants from us at market leading prices.

Product Details:

It is water based coating method done on metal components. Coating is done by keeping the component connected to a circuit as the cathode and positively charged paint particles (anode) suspended in aqueous medium are deposited under direct current. Deposited film does not re-dissolve and the un-deposited material is rinsed off.

CED coating is preferred because of its:

Ø Uniform coating thickness without porosity

Ø Parts of complex shapes and cavities can be fully covered

Ø Efficient utilization of coating materials

Ø Covers a wide range of materials (aluminium and steel castings, forgings and sheet metal components)

Ø Relatively high speed coating

Ø Aqueous process, hence free of fire risk

Ø Environmental friendly

Ø Superior chemical resistance

Ø Mechanical durability

Ø High Salt Spray life

Ø Good corrosion resistance

The CED plants offered by us are basically of 2 types:

Ø Dunking type

Ø Conveyorised type

Exceptional Durability and Protection

Our CED Plant stands out for its robust construction, rust- and flame-proof design, and reliable protection system. It's engineered to handle demanding industrial environments, providing years of reliable performance. The surface phosphatizing process ensures superior adhesion and corrosion resistance, safeguarding your products against harsh elements while maintaining optimal aesthetics.

Consistent and Efficient Coating

Achieve a perfectly even coat every time with the easy-to-operate CED Plant. The electric-powered system offers consistent output, minimizing manual intervention and maximizing productivity. This equipment is specifically crafted for professionals who need precision and quality without compromise, ensuring each application meets strict industry standards.

FAQ's of CED Plant:

Q: How does the CED Plant ensure even and high-quality coating?

A: The CED Plant features advanced electric-powered technology and precision engineering, which allows it to apply coatings evenly across surfaces. The phosphatizing process further enhances coating adhesion, resulting in a uniform and high-quality finish for each project.Q: What are the primary benefits of using the CED Plant?

A: This equipment provides strong, flame-proof, and rust-proof coatings, significantly improving the durability and lifespan of treated items. Additionally, its user-friendly operation and built-in protection system offer enhanced safety during use.Q: Where is the CED Plant typically used?

A: The CED Plant is mainly utilized in industrial settings, such as manufacturing units and production facilities, where robust surface protection and corrosion-resistant coatings are crucial for product longevity and performance.Q: When should I perform maintenance on the CED Plant?

A: Regular maintenance should be conducted as recommended in the user manual or as observed in operational performance. Routine checks help maintain the durability, safety, and efficient functioning of the equipment, keeping it within warranty terms.Q: What is the process for coating with the CED Plant?

A: The process starts with phosphatizing the surface, which prepares it for even coating. Once prepared, the electric system applies the coating in a controlled and consistent manner, ensuring comprehensive coverage and optimal protection.Q: How easy is the CED Plant to operate for new users?

A: The CED Plant is designed with user-friendliness in mind. Its clear controls and straightforward operation make it accessible for operators of various skill levels, so minimal training is required to achieve high-quality results.Q: What type of warranty is provided with the CED Plant?

A: The CED Plant comes with a one-year warranty, covering manufacturing defects and ensuring peace of mind for buyers throughout the initial period of use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CED Plants Category

CED Coating Plant

Price 5300000 INR / Unit

Minimum Order Quantity : 1 Set

Dimension (L*W*H) : Standard / Customizable

Temperature Range : 20C 30C

Equipment Type : Other, CED Coating Plant

Voltage : 380 440 volts Volt (v)

CED Coating Plant

Price 500000 INR / Unit

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : Customizable as per requirement

Temperature Range : 20C to 30C

Equipment Type : Other, CED Coating Plant

Voltage : 415 V AC, 3 Phase, 50 Hz

Cathodic Electro Deposited Plant

Price 1750000 INR / Unit

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : 12000 mm x 3000 mm x 4500 mm

Temperature Range : 22C 32C

Equipment Type : Electroplating Machine

Voltage : 380 V / 415 V

CED Plant

Price 5500000 INR / Plant

Minimum Order Quantity : 1 Plant

Dimension (L*W*H) : 4000 x 3000 x 2500 mm Millimeter (mm)

Temperature Range : 28 32C Celsius (oC)

Equipment Type : Electroplating Machine

Voltage : 380 V Volt (v)

Get A Quote

Get A Quote

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free